Wire Rope Testing

Alternate layers of right hand and left hand lay strands causes numerous point contacts along the entire length of rope. These point contacts see high stresses when the rope is loaded causing localised deformation and wear. Repeated bending under load adds to the problem as fatigue cracks form at the contact points, eventually causing the wires to break. This internal degradation is the primary cause of unexpected wire rope failure and as a result, all safety critical industries recognise the need for WRT in assessing the condition of ropes.

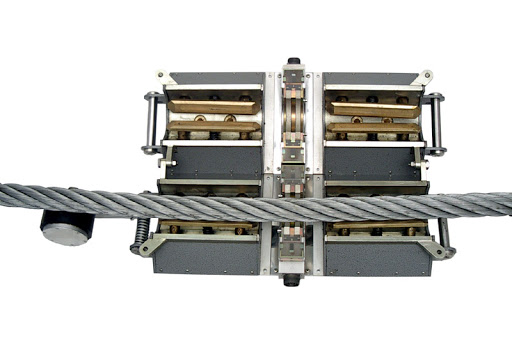

The method is based on magnetisation of the rope with permanent magnets and detection of the changes of magnetic field around the rope and total magnetic flux.

- The safe operation of wire rope is always in a completely controlled monitoring state.

- The inspection is completed during production, thus leading the two processes of production and inspection combined into one, effectively improving the utilization rate of equipment.

- It can reduce energy consumption of the equipment used for wire rope detection, save energy and reduce consumption significantly;

- It can scientifically extend the service life of wire rope and reduce the cost of wire rope.

TCK.W series products comply with wire rope safety bearing capacity checking principle in the international standard (ISO3154), correctly assess the residual bearing capacity and service life of the tested wire rope in-service through quantitative testing to the effective cross-sectional area loss percentage of actual load-bearing metals caused by various internal and external wire breakage, abrasion, fatigue and other damages , providing users with scientific basis for safe use and reasonable replacement in accordance with standards and specifications, and are High-tech guarantees in preventing effectively rope breaking accidents, reasonably reducing the cost of ropes and scientifically improving wire rope operating efficiency.

How to choose an excellent testing equipment

In China good and poor wire rope quality inspection devices are mixed, some fakes equipment pretended real ones , bad money drives out good money. If the customer chooses one test equipment that is not easy to use or even cannot be used, it will not only achieve the safety management goal of the wire rope, but will increase the new safety hazard. At the same time, purchasing a backward technology device will also bring unnecessary economic loss to enterprise。

“The way to distinguish a horse and mule is to pull them out and make them walk” It is the great wisdom of the Chinese to make the right choice. “Marrying by contesting” or “verification results” is the correct way to choose excellent equipment. Seeing is believing, and the result is the first, Using the flaw detection rate, repetition rate, accuracy rate to verify the quality of the equipment, the poor quality equipment are very easy to expose.