Magnetic Particle Testing

Magnetic Particle Non-Destructive Testing is the act of identifying imperfections in a material by examining disruptions in the flow of the magnetic field within the material. This method is used for the detection

Read More

Penetrant Testing

Liquid Penetrant Non-Destructive Testing is a simple, inexpensive and reliable non-destructive inspection method for detecting discontinuities which are open to the surface of the item to be inspected.

Read More

Ultrasonic Testing

Ultrasonic Non-Destructive Testing is the process of transmitting high-frequency sound waves into a material in order to identify changes in the material’s properties

Read More

Eddy Current Testing

In Eddy current testing, a coil carrying an AC current is placed close to the specimen surface, or around the specimen. The current in the coil generates circulating eddy currents in the specimen

Read More

Radiography Testing

Radiography Testing uses X-rays or gamma-rays to produce an image of an object on film. The image is usually natural-size. X-rays and gamma-rays are very short wavelength electromagnetic radiation

Read More

Visual Testing

Visual Testing is the observation, either directly or indirectly (remotely), of a specimen by an Inspector in such a fashion as to determine the presence or absence of surface discontinuities or irregularities.

Read More

Phased Array Ultrasonic Testing

Phased Array Ultrasonic Testing typically consists of a transducer assembly with from 16 to as many as 256 small individual elements that can each be pulsed separately.

Read More

Time Of Flight Diffraction( TOFD ) Ultrasonic Testing

In Time of flight diffraction (ToFD) systems, a pair of ultrasonic probes are used, sitting on opposite sides of a weld-joint or area of interest. A transmitter probe emits an ultrasonic pulse

Read More

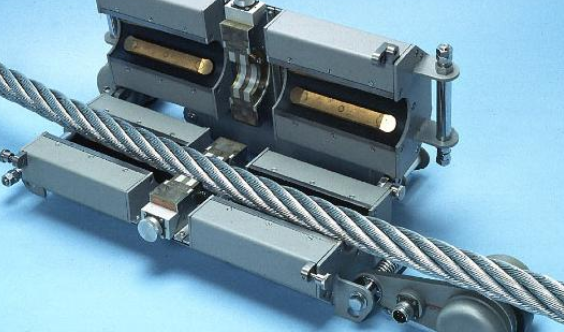

Wire Rope Testing

Alternate layers of right hand and left hand lay strands causes numerous point contacts along the entire length of rope. These point contacts see high stresses when the rope is loaded causing localised deformation and wear.

Read More

Magnetic Flux Leakage (MFL)

Magnetic Flux Leakage (MFL) uses a powerful magnet to magnetize the conductive material under test (usually steel). Where there are defects — corrosion or material loss — the magnetic field “leaks” from the steel.

Read More

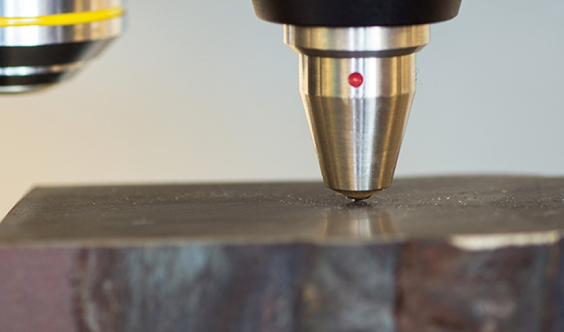

Hardness Testing

Hardness Testing (HT) is today one of the most frequently employed methods for mechanical material testing, in particular for metals. On the one hand, this test method allows qualitative relationships to other

Read More

Thickness Gauging ( UTG ) Ultrasonic Testing

Ultrasonic Thickness Measurement (UTM) is a widely used non-destructive testing technique for measuring the thickness of a material from one side. It is fast, reliable, and versatile.

Read More

Holiday Testing

A holiday test is an inspection method used to detect discontinuities in painted/coated surfaces using specialized tools and equipment. These tools, called holiday detectors, are portable devices that are swept

Read More

Hatch Cover Inspection

Ensuring a ship’s hatch covers are weather tight is an essential aspect of exercising due diligence to make a ship cargo worthy that may not be covered by routine classification society inspections.

Read More

Ground Penetrating Radar ( GPR Testing )

Ground penetrating radar (GPR) operates by transmitting electromagnetic waves (in the range of 10 ~ 1000 Hz) into the probed material and receiving the reflected pulses as they encounter discontinuities.

Read More